For over 40 years, we have been producing exquisite Italian delicacies, ready to be tasted and full of the good flavours of nature.

Let yourself be tempted by the authentic, intense and genuine flavours of nature. With Nova Funghi you can bring to the table a wealth of ready-to-taste specialities: mushrooms, artichokes, olives, asparagus, grilled vegetables and vegetable creams,, the perfect companions for all your creations and the perfect treat. You can taste the difference and the flavour immediately.

Our system: a quality guarantee

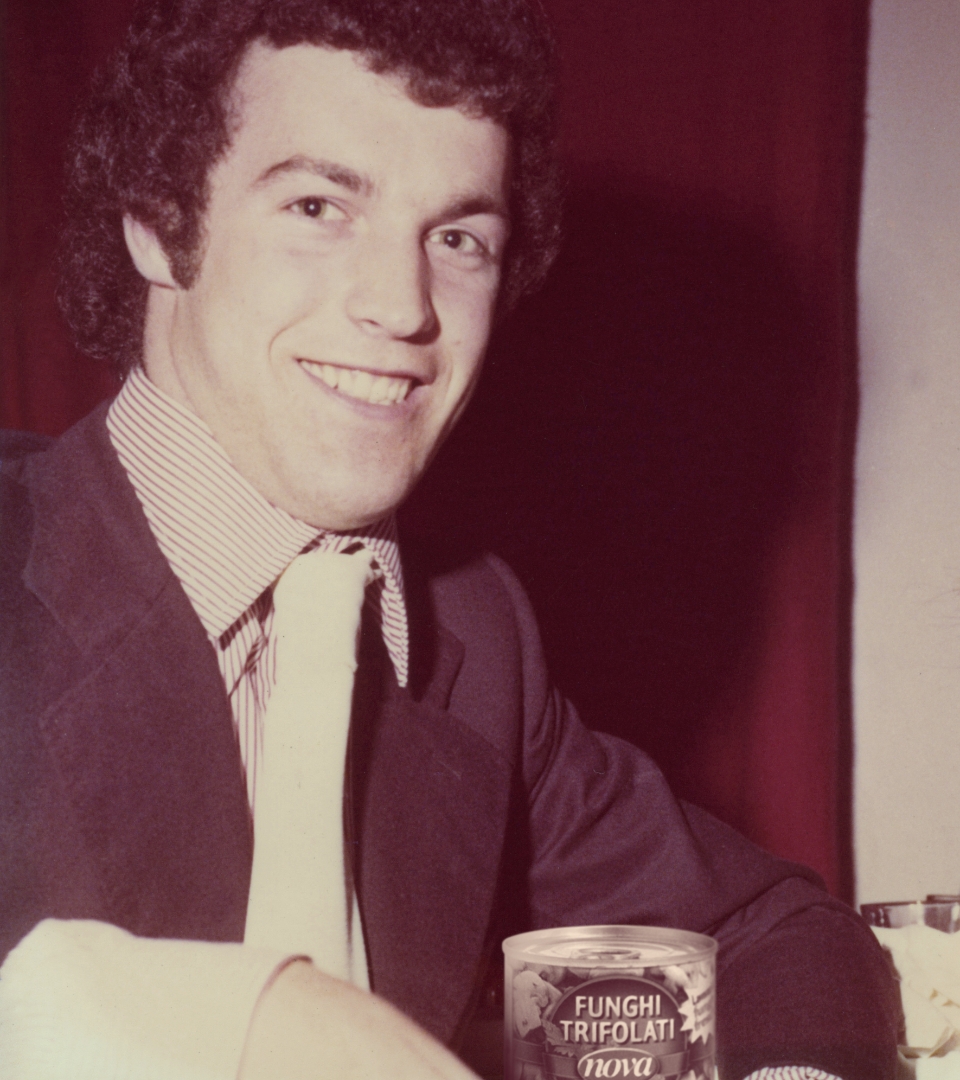

Food requires respect, precision and culture, because“we are what we eat”. This is the philosophy with which Paolo Scapin founded Nova Funghi in 1980, creating a vast range of delicacies and a plethora of dedicated production lines.

We can proudly assert that our products are subject to strict and thorough checks, both at the very beginning and throughout the production cycle, thanks to qualified personnel and cutting-edge equipment, such as metal detectors, X-rays and optical sorting machines that can ascertain the presence of even the smallest foreign, non-organic bodies.

Our production process is well organised and can guarantee that raw materials are processed as soon as they arrive at the company. This ensures that, when the fresh mushrooms arrive a few hours after being picked, they are processed immediately and their genuine and crisp taste is preserved intact.

We should also point out that, during the processing cycle, the mushrooms are cooked with a special process, one of its kind, conceived by Nova Funghi. Our secret? Double stage steam cooking which is exactly what it says: the mushrooms are steam cooked in two stages in a process that is characterised by an immediate lowering of the temperature, thus optimising the mushrooms’ cooking without stressing the product and preserving all its properties. This also makes it possible to preserve the mushrooms’ fragrance and keep them from oxidising.

Once the cooking stage is over, the mushrooms are gently sliced by an H2O cutting machine. The product is not subjected to any additional stress and is then seasoned and transferred to the various packaging departments. At the end of the processing cycle, the mushrooms are sterilised. This operation guarantees a 36-month shelf-life and ensures that the mushrooms retain all their organoleptic characteristics.

Being Italian is synonymous

with flavour and quality

We carefully choose the best vegetables and genuine ingredients to prepare our delicious products. We look for exquisite, high-quality and natural products, starting with mushrooms.

Where market vegetables are concerned, we select small producers from diverse areas, where the soil and climate are best suited to the various crops. We do this in order to have fresh and flavoursome vegetables throughout the year. Choosing the right raw materials is fundamental for obtaining high-quality products.

We process and package the vegetables and mushrooms solely in our plant, thoroughly checking all steps and guaranteeing the highest safety levels. The management of our production and supply chain is still a family affair, with respect for tradition and Italian flavours.

1. Conscious crop husbandry

We sustainably support a network of quality farmers who grow our mushrooms and our vegetables. We create long-term, trust-based relationships with the best suppliers, ensuring we only receive excellent, flavoursome and genuine raw materials.

2. Long live sustainability!

Our products are also good for the environment. The packaging that protects them is mostly produced from recyclable materials. In our transformation plants we produce with a focus on energy savings, reducing consumption and waste.

3. Processing that respects the raw materials

We adopt precise processes to handle fresh products gently and in the most natural manner possible. Exclusive production techniques ensure that the authentic flavour and the precious organoleptic characteristics of the vegetables and mushrooms are preserved, as if they had been freshly picked.

4. Waste-free production

We pay great attention to preventing food waste and to reducing the by-products of the production process to a minimum. Thanks to efficient and modern systems, we process the raw materials saving energy and water.

5. CO2: boo!

All details of our packaging are carefully thought out to reduce weight and volume, thanks to new materials and innovative solutions. They take up less space and are easier to transport. In this way, we can optimise shipping and reduce carbon dioxide emissions during deliveries.

6. Insatiably curious

We always keep an eye out for the new taste trends and are guided by the preferences of lovers of good food, to create and improve our products: mushrooms and vegetables preserved in oil.

Quality

We pay minute attention to every detail when preparing mushrooms, vegetables and vegetable creams, so that you can be sure that the products you put on your table are natural, healthy and genuine. Starting with the meticulous management of the production and supply chain, we select the best suppliers and keep a close eye on the quality of ingredients, from the word go. All processing stages take place inside our plants, where we can personally ascertain that all hygiene rules are respected, preventing contamination and preserving the organoleptic characteristics of the foods. Food safety is guaranteed by thorough testing and full compliance with the applicable rules and regulations.

Before being placed on the market, the products undergo a rigorous testing and control schedule.

Certifications

Tastiness is now certified. Every day, we strive to guarantee flavoursome and genuine products. The excellence of our processes is guaranteed by the IFS Certification, while we are planning to obtain other important International Standards.

IFS Certification

The International Food Standard is one of the most important international food certifications. It guarantees the quality and safety of our products that you find in supermarkets.

Private label:

your brand, our experience.

Thanks to cutting-edge systems, we can now make our experience and our ability available to private label and large supermarket chains for the manufacture of customised private label products in various formats: in glass, in pouches, and in trays. We have always sought to maximise the quality of our products through technological innovation. We continuously invest in upgrading the packaging lines to reduce processing times, thus preserving the natural flavour of the fresh vegetables, tinned foods and mushrooms, with utmost respect for food safety.

Work with us

Send us your spontaneous application